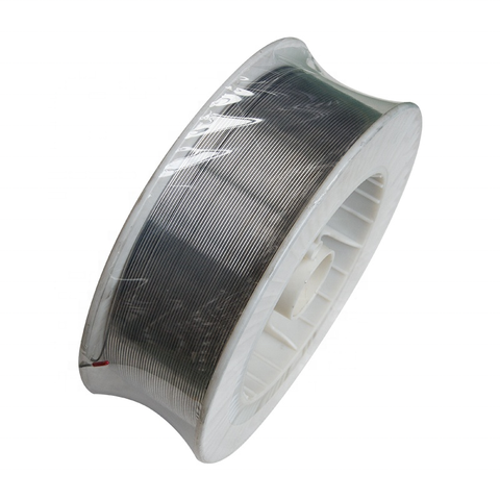

Beryllium copper

Beryllium copper alloy generally refers to beryllium bronze. Beryllium bronze is a tin-free bronze with beryllium as the main alloying group element, containing 1.7 to 2.5% beryllium and a small amount of nickel, chromium, titanium and other elements. After quenching and aging treatment, its strength limit can reach 1250-1500MPa, close to the level of medium strength steel. In the quenched state, beryllium bronze has good plasticity and can be processed into various semi-finished products. This material has high hardness, elastic limit, fatigue limit and wear resistance, as well as good corrosion resistance, thermal conductivity and electrical conductivity. Beryllium bronze does not produce sparks when impacted, so it is widely used in the manufacture of important elastic components, wear-resistant parts and explosion-proof tools. Commonly used beryllium bronze grades include QBe2, QBe2.5, QBe1.7, QBe1.9 and so on.

Beryllium copper alloy (beryllium bronze) has the following characteristics and uses.

High strength and hardness: making it suitable for applications that require high loads.

Good electrical and thermal conductivity: suitable for applications with high electrical and thermal conduction requirements.

High abrasion and corrosion resistance: suitable for the manufacture of parts in harsh environments.

Non-sparking properties: suitable for use in flammable and explosive environments, such as the manufacture of explosion-proof tools and equipment.

Wide range of applications: including but not limited to temperature controllers, cell phone batteries, computers, automotive parts, micro motors, brush pins, advanced bearings, eyeglasses, contact parts, gears, punches, non-sparking switches, electrodes for welding and precision casting molds, etc. 2.

In addition, beryllium copper alloy also has good processing performance and cooling effect, so that it has a wide range of applications in industrial production prospects